The Role of Machine Tools in the Automotive Industry

The automotive industry utilizes a wide range of materials but mainly relies on steel since it is strong, lightweight, and relatively inexpensive. These properties make it an ideal material for producing many automotive components like axles, engine mounts, shafts, the body, and more.

Precision and Volume in Automotive Manufacturing

In automotive manufacturing, achieving precise cutting, complex geometries, and joining of metal components while sustaining high production volumes can be a challenge. To overcome this, the industry has begun embracing automation, particularly through the use of CNC machining; This allows manufacturers to consistently and rapidly produce large quantities of parts and components.

Metal Stock and Cutting in the Automotive Manufacturing Process

In automotive production, the metal material is typically cut down from its stock form using advanced machinery. An operator will then load the workpiece and secure it to the working area of the machine where it will need to be programmed to cut and form the metal. The operator might program right at the machine or for more intricate geometries a CNC Programmer will be needed. There are several machines used in automotive production that can be utilized to cut down the stock material. The most common are plasma cutters, laser cutters, and waterjets. These machines are capable of handling large volumes quickly with minimal mistakes and waste, reducing production costs.

Highly Efficient Grinding Machines

Grinders play a critical role in creating a number of components for the automotive industry. These machines are engineered for precision with efficiency in mind for shorter cycle times. Many industrial grinders have features for full automation, allowing them to be seamlessly integrated into the production line. Grinding wheels remove material from the workpiece surface and enhance its shape and surface finish.

Automated Drilling Machines in Automotive Manufacturing

High-volume deep-hole drilling machines are used by many automotive manufacturers to meet the demands of production and accuracy mainly for transmission parts. Deep-hole drilling systems are designed with the reliability needed to run continuous production and are often paired with automation solutions for manufacturers.

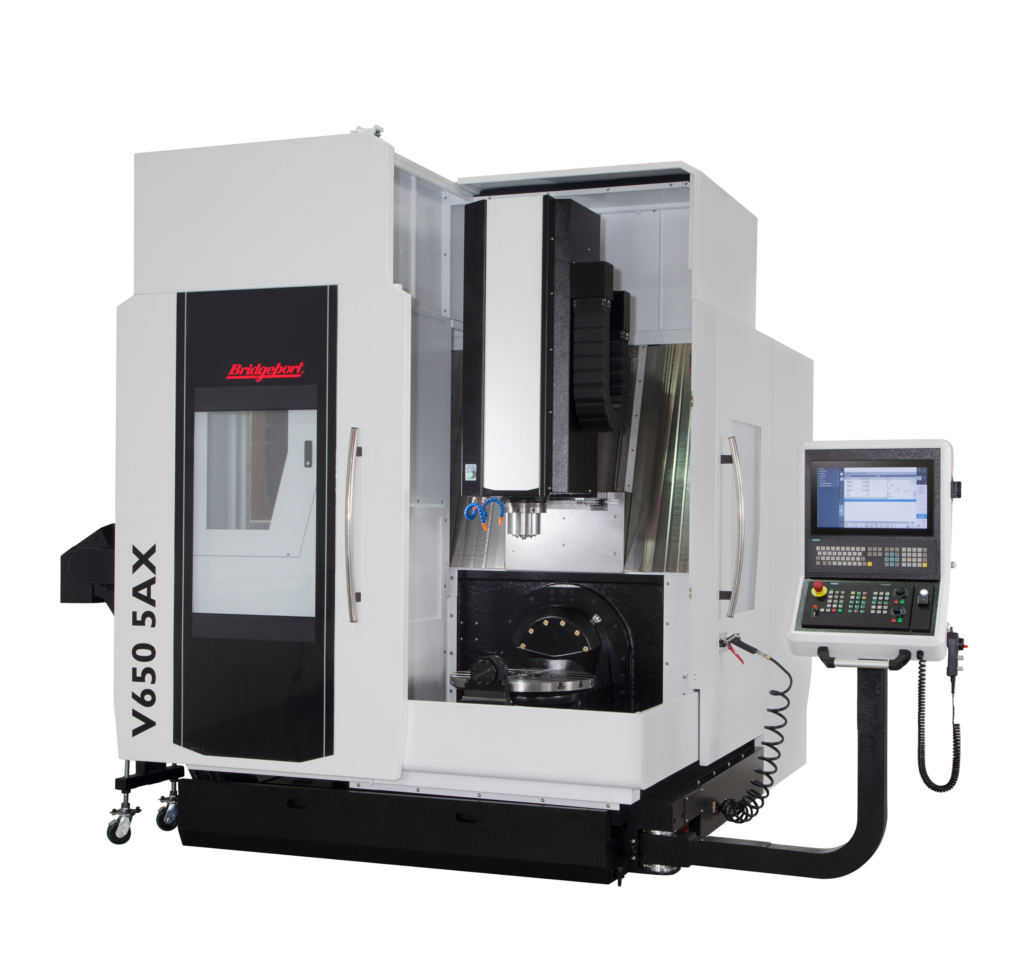

Milling Machines: Cutting and Shaping Metal

Milling machines are versatile tools used to cut and drill metal, creating holes, smoothing surfaces, and forming indentations for fitting metal pieces together. In the automotive industry, both vertical and horizontal milling machines are employed to shape body panels and machine other car parts and components. Milling involves a rotary cutter that spins around an axis while the metal workpiece advances, shaving off material with each pass. Computer controls ensure the precision of these operations, allowing for the accurate production of complex parts. By leveraging these advanced machining tools, the automotive industry continues to innovate and improve its manufacturing processes, ensuring the production of high-quality, reliable vehicles.

June 11, 2024 | Views | Categories: Article, CNC Machines

Related Posts

Latest Posts

Categories

Article

Guide

Tips

Topics

CNC Machines

Standard Machines

Tags

Clausing

CNC Lathes